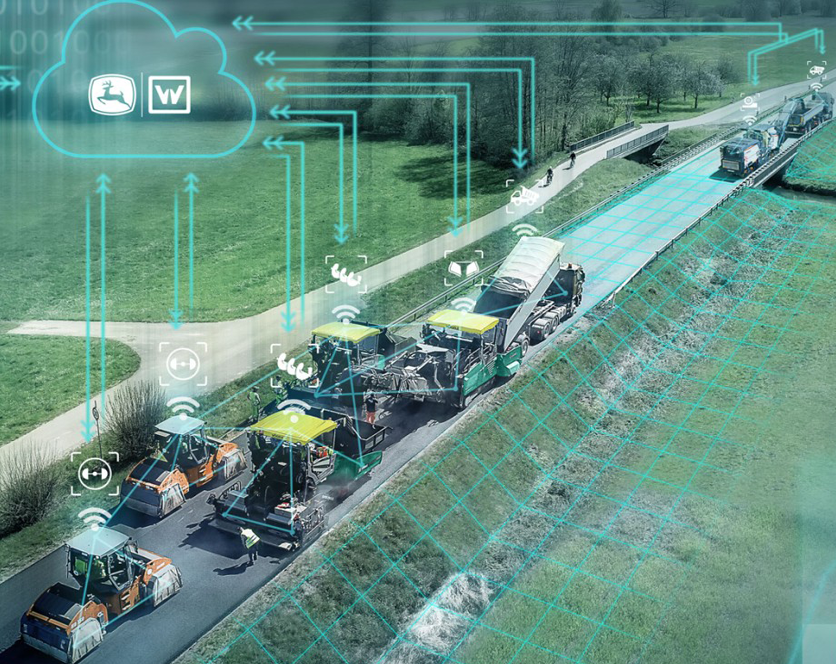

Achieve Reliable Quality -- From Planning to Paving

With WIRTGEN's Smart Automation in Roadbuilding, you're no longer shooting in the dark when it comes to milling and paving. Drawing on digital terrain models, the system enables your machines to operate with pinpoint accuracy -- from milling depth and cross-slope right through to screed position and paving line.

Key Benefits:

- Predictable final results -- less guesswork.

- Significantly improved precision on asphalt reclamation and paving.

- Full integration into your machine fleet -- no major retrofits needed.