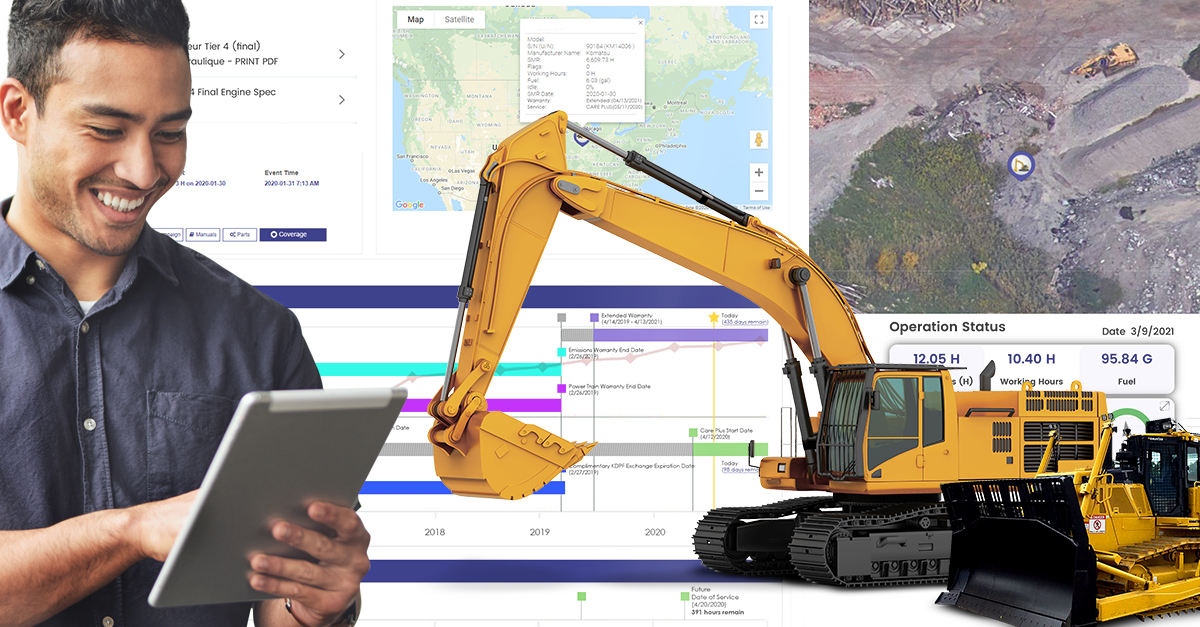

Designed to collect, visualize and monitor telematics data from Komatsu and non-Komatsu machines

With Komatsu’s comprehensive digital hub, My Komatsu, contractors can get easy-to-interpret visual analyses of data collected from numerous sources displayed on easy-to-read dashboards. My Komatsu can pull data from Komtrax, Komtrax Plus, ISO API 15143-3 (AEMP 2.0) data from other OEMs, or other direct data sources and provide powerful analytics to help you manage your fleet and drive your business without managing multiple IDs and passwords.

“Komatsu understands that our customers are busy and expect technology to be easy to use,” said Matthew Beinlich, director of digital support solutions for Komatsu. “Starting today, our customers can get the most important telematics data, such as location, hours, fuel consumption, idle ratio and production, from My Komatsu for many of the other brands of equipment they may operate. Enter the ISO 15143-3 API credentials for those brands into My Komatsu once, and you’ll no longer need to log into each OEM’s system separately each day.”

The system has been designed to make it easy to collect, visualize and monitor telematics data from both Komatsu and non-Komatsu machines.

• Quickly view and manage data on one dashboard

• Receive maintenance alerts and order parts

• Troubleshoot to help minimize downtime

• Monitor for theft and unauthorized use

• Benchmark machine performance

• Track fuel consumption and manage fuel efficiency

• Access data anytime

With the ISO-15143-3 (AEMP 2.0) telematic API (application programming interface), computer code allows fleet managers to integrate new telematics digital information into existing fleet management systems. With this functionality, fleet managers can view telematics data for Komatsu and non-Komatsu machines to easily visualize the complete fleet, pull operation reports and set alerts.

Here's how it works:

- Data is generated by equipment (Komatsu or non-Komatsu)

- Komatsu data flows to Komtrax data storage. ISO 15143-3 (AEMP 2.0) facilitates the extraction and raw data to your choice of database

- My Komatsu connects telematic data from all equipment or accesses it through monitoring and analysis services to create powerful analytics dashboard views

ISO integration and analytics are currently standard features with a My Komatsu registration. Learn more about getting insights that can benefit your bottom line at komatsu.com/mykomatsu.